1 Gasification coupling power generation process

There are three main ways of biomass coupling power generation: direct coupling, gasification coupling and steam coupling. Direct coupling refers to the process of mixing pulverized biomass and coal directly in the boiler of power plant; For gasification coupling, a separate gasifier needs to be set. After biomass gasification, the produced gas will be introduced into the boiler of the power plant for mixed combustion; The process that biomass is burned in a separately set boiler and the generated steam is incorporated into the steam header of the power plant boiler is called steam coupling.

The process characteristics of different coupling modes are different. Based on the application of the mature coupling power generation technology in Europe, the power generation efficiency and unit investment of different coupling modes are compared. The comparison results are shown in Table 1.

From the comparison data, the direct coupling method is in an advantageous position in terms of transformation cost and power generation efficiency, but it has high requirements on biomass type and pretreatment depth, which is easy to cause slagging and corrosion problems, and will also affect the ash properties of coal-fired boilers and reduce the utilization value. The steam coupling avoids the impact of biomass on the original equipment by setting a combustion boiler separately. The proportion of biomass mixed combustion is only limited by the power generation steam turbine, but it needs to add a separate purification system such as dust removal, which will greatly increase the investment cost. The efficiency of gasification coupling power generation is close to that of steam coupling, but the investment cost has been reduced by nearly 1/2. Through gasification, the impact of biomass on coal-fired boilers has been reduced, the types of consumable raw materials have been expanded, which is convenient for the collection and comprehensive utilization of ash, and the existing air purification system can be used to meet the emission requirements, which is an ideal coupling method. Therefore, biomass gasification will become the mainstream coupling process in consideration of the coupling power generation metering problem and the inclination of national policies.

2 Comparison of biomass gasifier technologies

The biomass gasification reaction needs to be completed in the gasifier. According to the different gas-solid contact modes, the biomass gasifier is mainly divided into fixed bed (upper suction type, lower suction type), fluidized bed (bubbling fluidized bed, circulating fluidized bed) and entrained flow bed; It can be divided into atmospheric and pressurized gasifiers according to different operating pressures. The entrained flow bed has a high requirement on the particle size of biomass (particles<3mm) and is not suitable for large-scale biomass treatment process. Therefore, the current biomass gasification technology is generally fixed bed and fluidized bed. The difference between the structure of fixed bed gasifier and fluidized bed gasifier affects its treatment scale, gas characteristics and quality, thus determining the application occasions of different types of gasifiers.

(1) Applicable scale of different gasifier types. The mixing degree and heat conduction in the fixed bed gasifier are relatively poor, which makes it difficult to achieve uniform material distribution, temperature distribution and gas composition in the same section. The above problems will become more serious with the size enlargement. Relatively speaking, the fluidized bed gasifier has more strict requirements on the size of raw materials, but its material and temperature uniformity is better, its operation is more stable, and it has more advantages in the treatment scale. Under normal operating conditions, the processing capacity of different gasifiers using conventional straw as raw material is shown in Figure 1. It can be seen from Figure 1 that the processing capacity of the atmospheric fluidized bed gasifier can reach about 100MW (about 600t/d), while the processing capacity of the fixed-bed gasifier does not exceed 10MW (about 60t/d). Since the coupled power generation needs to reach a certain scale to have higher economic benefits, the fluidized bed gasifier with greater processing capacity will have more advantages [3].

(2) Tar output of different gasifiers. Biomass gasification is often accompanied by tar production, which causes energy waste, reduces gasification efficiency, and affects the stable operation of gasification equipment. Unpurified biomass gas will also cause serious harm to subsequent pipelines and combustion equipment.

Due to the different structures of different gasifiers, the tar production is quite different, among which the gas from the updraft fixed-bed gasifier cannot be completely cracked because it passes through the low temperature zone, and the tar content is the highest; The downdraft fixed-bed gasification gas can ensure sufficient pyrolysis temperature, with the minimum tar content, and the bubbling and circulating fluidized bed gasifiers are between the above two. See Table 2 [4, 6] for specific data.

(3) Gas composition of different gasifier types. The composition of biomass gas is the key factor to determine the calorific value and combustion performance of the gas. The ideal gas composition can ensure higher coupling power generation parameters. Under the condition that air is selected as gasifier, the composition of gas produced by different types of gasifiers is shown in Table 3.

It can be seen that the fixed bed gasifier and the fluidized bed gasifier have relatively high gasification efficiency due to the difference in gas calorific value, but because the temperature and material distribution inside the fluidized bed are more uniform, the gas production and gas composition are relatively stable, and the gas quality is higher [4, 6].

(4) Selection of gasification coupling power generation furnace type. Due to its own limitations, fixed bed gasifiers are not suitable for biomass coupling power generation projects in coal-fired power plants. First of all, the fixed bed gasifier has a small scale (generally<10MW) and cannot produce scale effect, which limits the possibility of project profit. Secondly, the feeding process of fixed bed gasifier is easy to produce bridging phenomenon and difficult to control, so the gas quality fluctuates greatly, affecting the safe operation of the boiler. The up-suction fixed bed with relatively large treatment scale is not suitable for the coupled power generation process because of its low outlet gas temperature (about 450 ℃) and large fluctuation, and high tar content in the gas. The fixed-bed gasifier is more suitable for the small scale of biomass treatment, in which the up-suction fixed-bed is more suitable for the occasions where the crude gas does not need to be cooled and purified, such as directly serving as fuel for small boilers or heating furnaces or providing process heat source for the system; The downdraft gasifier can work well with the internal combustion engine due to its low tar content, and is suitable for distributed gasification power generation under 1MW.

According to the estimation of domestic gasification coupling operation, the coupling power generation needs to reach a certain scale to have high economic benefits, and the converted unit power generation capacity is at least about 15 MW. At the same time, in order to reduce the impact on boiler combustion, the calorific value and gas volume of gasification gas should also have high stability. Due to its good mixing effect, uniform temperature distribution and stable operation effect, the fluidized bed gasifier is more suitable for coal-fired power plant gasification coupling power generation, large-scale gasification power generation, gasification of synthetic gas to produce high value-added biofuel and other occasions, and also suitable for small and medium-sized cities and towns biomass (including garbage) gasification heating. Therefore, for the biomass coupling power generation project of coal-fired power plant, it is most suitable to adopt the fluidized bed gasifier technology with high operation stability, especially the circulating fluidized bed with higher load flexibility and more uniform raw material mixing.

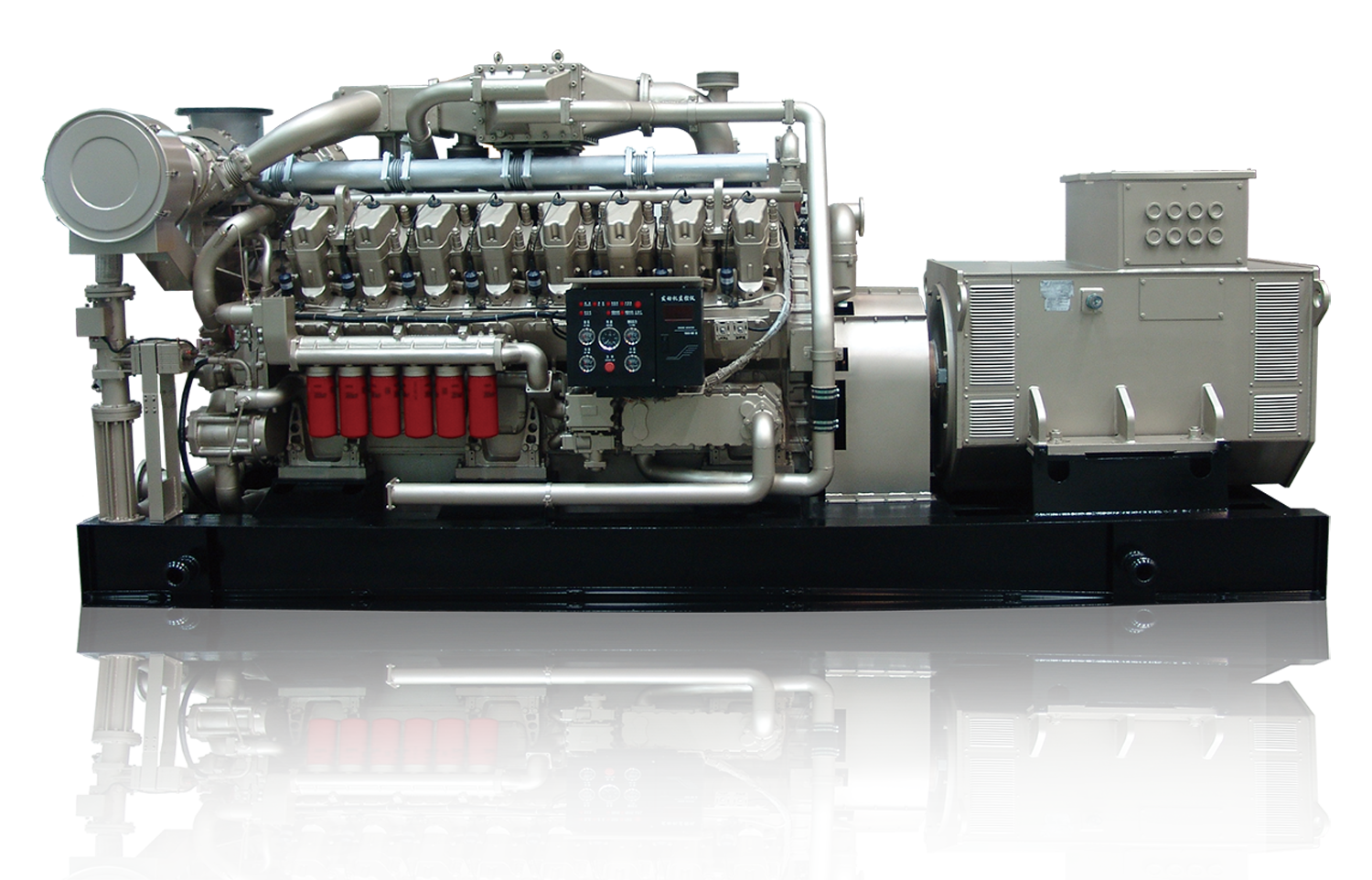

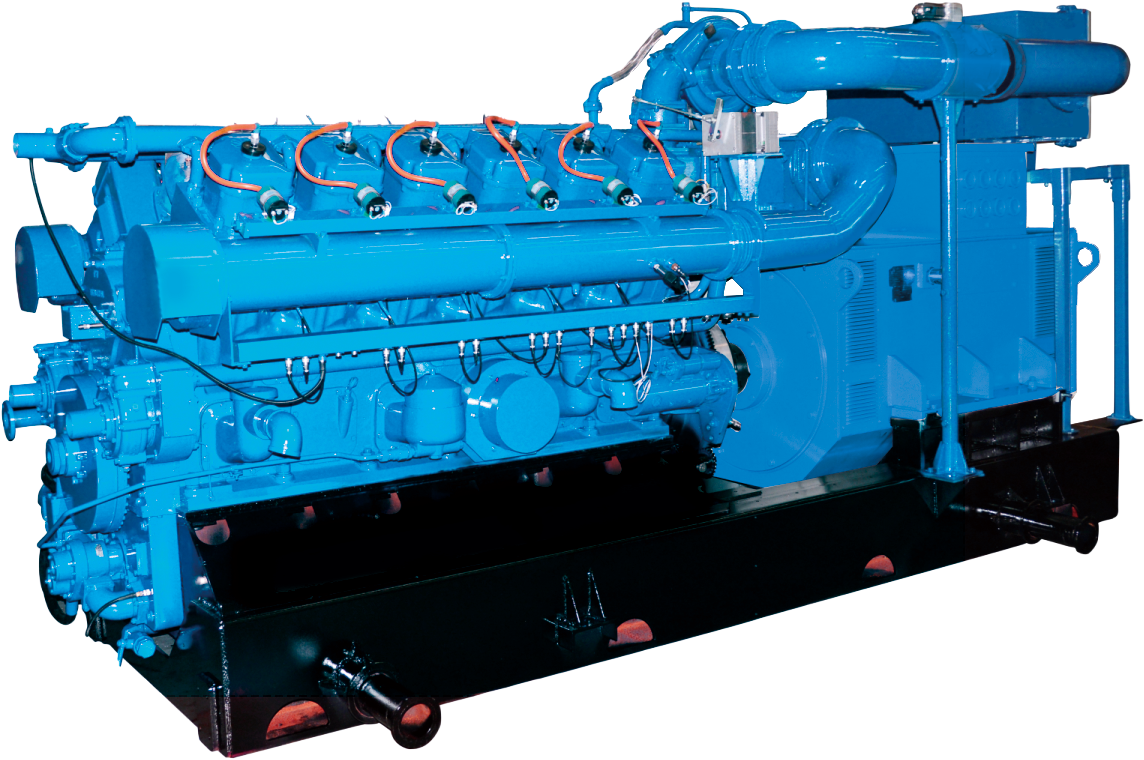

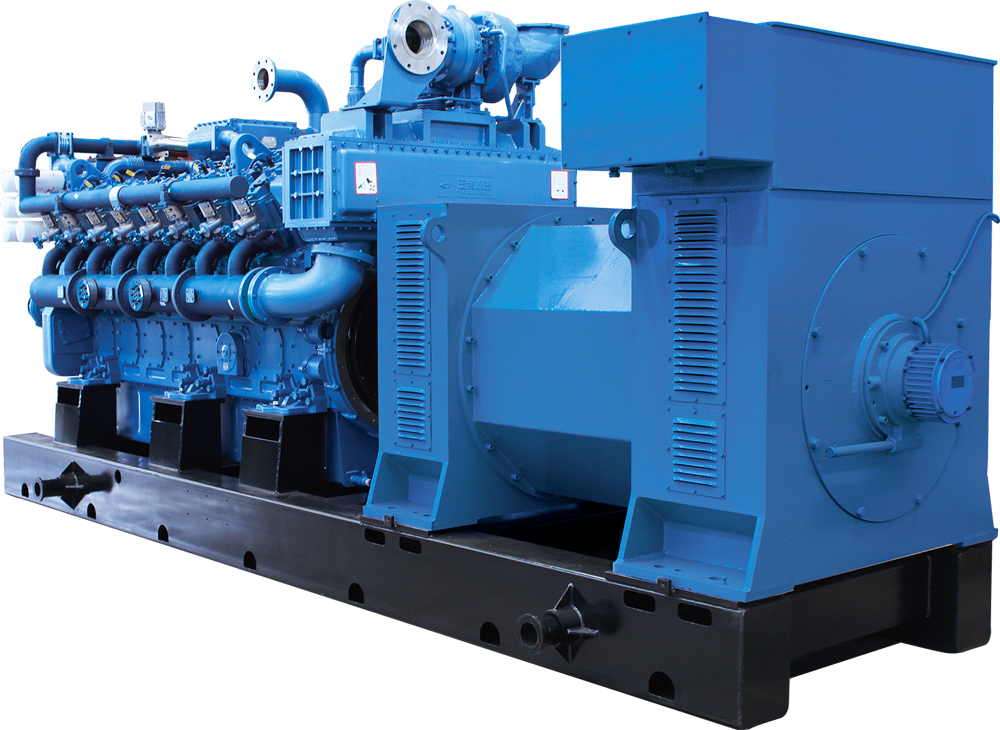

This article is supported by the pyrolysis gas generator unit. For more details, please click our website http://www.peldhb.com , we will wholeheartedly provide you with satisfactory service.

Tel:0531-69953988

Tel:0531-69953988  Add:101, Building 5, Liandong U Valley Science and Technology Innovation Center, Zhangjin Comprehensive Bonded Zone, No. 33688 Jingshi East Road, Suncun Street, Jinan Area, China (Shandong) Pilot Free Trade Zone

Add:101, Building 5, Liandong U Valley Science and Technology Innovation Center, Zhangjin Comprehensive Bonded Zone, No. 33688 Jingshi East Road, Suncun Street, Jinan Area, China (Shandong) Pilot Free Trade Zone