聯系 - 熱線

聯系 - 熱線

0531-69953988

聯系 - 熱線

聯系 - 熱線

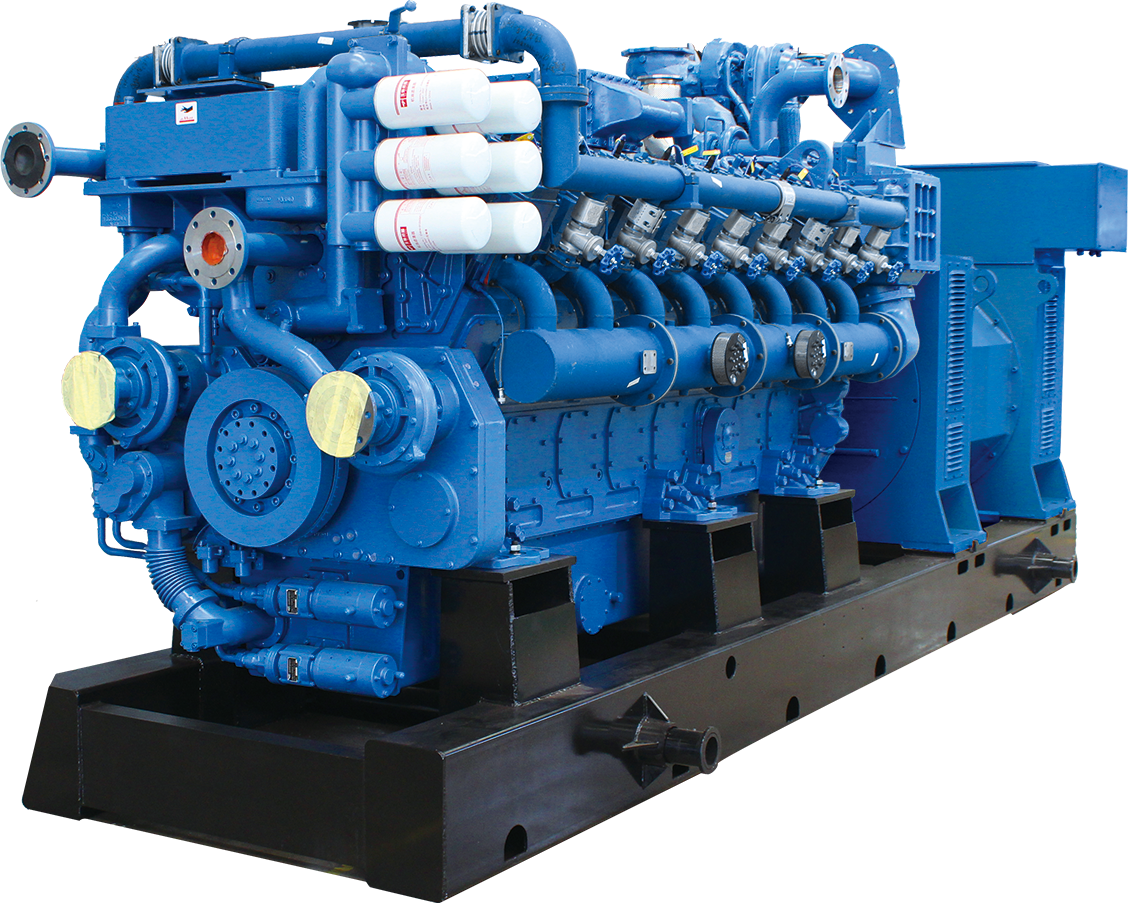

冶金行業中燃氣發電機組的作用與優勢

冶金行業作為高能耗產業,生產過程中既需要穩定的電力供應,又會產生大量可燃氣體(如高爐煤氣、轉爐煤氣),燃氣發電機組通過回收利用這些氣體發電,實現了能源的循環利用,在保障生產、降低成本、減少排放等方面發揮著不可替代的作用,成為冶金企業構建綠色生產體系的重要設備。

As a high-energy consumption industry, the metallurgical industry requires stable power supply and generates a large amount of combustible gases (such as blast furnace gas and converter gas) during the production process. Gas generator sets recycle and utilize these gases to generate electricity, achieving energy recycling and playing an irreplaceable role in ensuring production, reducing costs, and minimizing emissions. They have become important equipment for metallurgical enterprises to build a green production system.

能源自給與電力保障是燃氣發電機組在冶金行業的核心作用,能有效應對電網波動對生產的影響。冶金生產(如煉鋼、軋鋼)對電力穩定性要求極高,突然斷電可能導致熔爐凝固、設備損壞,造成巨大損失。燃氣發電機組可作為自備電源,利用生產過程中產生的可燃氣體(如高爐煉鐵時產生的高爐煤氣)發電,滿足廠區 30%-50% 的用電需求,部分大型企業的發電機組集群甚至能實現電力自給自足。在電網故障或限電時,發電機組可快速切換為應急電源,確保關鍵設備(如熔爐、水泵)正常運行,避免生產中斷。這種 “以氣發電、以電保產” 的模式,讓冶金企業擺脫了對外部電網的完全依賴,提升了生產連續性。

Energy self-sufficiency and power security are the core roles of gas-fired generators in the metallurgical industry, which can effectively cope with the impact of power grid fluctuations on production. Metallurgical production (such as steelmaking and steel rolling) requires extremely high electrical stability, and sudden power outages may cause furnace solidification and equipment damage, resulting in huge losses. Gas generator sets can be used as a self-contained power source to generate electricity using combustible gases generated during the production process (such as blast furnace gas produced during iron smelting), meeting 30% -50% of the electricity demand in the factory area. Some large enterprise generator sets can even achieve self-sufficiency in electricity. In case of power grid failure or power restriction, the generator set can quickly switch to emergency power supply to ensure the normal operation of key equipment (such as furnaces and water pumps) and avoid production interruption. This "gas power generation and electricity production guarantee" model has freed metallurgical enterprises from complete dependence on external power grids and improved production continuity.

回收可燃氣體、減少能源浪費是其另一重要作用,將原本排放的氣體轉化為寶貴的能源。冶金過程中,高爐、轉爐等設備會產生大量可燃氣體,若直接排放到大氣中,不僅浪費能源,還會污染環境(如煤氣中的一氧化碳是有毒氣體)。燃氣發電機組通過專用管道收集這些氣體,經凈化處理(去除粉塵、水分、硫化物)后送入燃燒室燃燒發電,使可燃氣體的利用率提升至 90% 以上。以高爐煤氣為例,其熱值雖較低,但通過發電機組的特殊燃燒系統可高效利用,每立方米煤氣可轉化為一定量的電能,一座中型高爐每年回收的煤氣發電量可達數千萬度,相當于節省數萬噸標準煤,大幅提高了冶金企業的能源利用效率。

Another important role of recycling combustible gases and reducing energy waste is to convert the originally emitted gases into valuable energy. During the metallurgical process, equipment such as blast furnaces and converters produce a large amount of combustible gases. If directly emitted into the atmosphere, it not only wastes energy but also pollutes the environment (such as carbon monoxide in coal gas, which is a toxic gas). Gas generator sets collect these gases through dedicated pipelines, purify them (removing dust, moisture, and sulfides), and send them into the combustion chamber for combustion and power generation, increasing the utilization rate of combustible gases to over 90%. Taking blast furnace gas as an example, although its calorific value is relatively low, it can be efficiently utilized through the special combustion system of the generator set. Each cubic meter of gas can be converted into a certain amount of electrical energy. A medium-sized blast furnace can recover tens of millions of kilowatt hours of gas for electricity generation every year, which is equivalent to saving tens of thousands of tons of standard coal and greatly improving the energy utilization efficiency of metallurgical enterprises.

降低生產成本的優勢顯著,體現在燃料成本與用電成本的雙重節約。燃料方面,發電機組使用的燃氣來自生產副產品,無需額外采購,與使用天然氣或柴油的發電機組相比,燃料成本幾乎為零,每年可節省大量燃料費用。用電方面,自備發電的成本(含設備折舊、維護費用)通常低于外購電網電價,尤其在電價較高的地區,這種成本優勢更為明顯。對于年產鋼量百萬噸級的企業,燃氣發電機組每年可降低電費支出數千萬元,同時減少因外購電產生的輸電損耗,進一步提升經濟效益。此外,發電機組運行過程中產生的余熱(如煙氣余熱、缸套水余熱)可回收用于供暖、加熱工藝水或預熱助燃空氣,實現 “發電 + 余熱利用” 的綜合效益,使能源利用率再提升 10%-20%。

The significant advantage of reducing production costs is reflected in the dual savings of fuel costs and electricity costs. In terms of fuel, the gas used by the generator set comes from production by-products and does not require additional procurement. Compared with generator sets that use natural gas or diesel, the fuel cost is almost zero, which can save a lot of fuel costs every year. In terms of electricity consumption, the cost of self generated electricity (including equipment depreciation and maintenance expenses) is usually lower than the electricity price of purchased power grids, especially in areas with higher electricity prices, where this cost advantage is more obvious. For enterprises with an annual steel production of millions of tons, gas-fired power generation units can reduce electricity bills by tens of millions of yuan each year, while also reducing transmission losses caused by purchased electricity, further enhancing economic benefits. In addition, the waste heat generated during the operation of the generator set (such as flue gas waste heat and cylinder liner water waste heat) can be recovered for heating, heating process water, or preheating combustion air, achieving the comprehensive benefits of "power generation+waste heat utilization" and increasing energy utilization efficiency by another 10% -20%.

減少污染物排放、助力綠色生產是其在環保方面的突出作用,符合冶金行業的減排要求。傳統上,冶金企業為處理多余的可燃氣體,常采用火炬燃燒后排放的方式,這不僅浪費能源,還會產生二氧化碳、氮氧化物等污染物。燃氣發電機組通過充分燃燒這些氣體,將一氧化碳轉化為二氧化碳(毒性大幅降低),氮氧化物排放量也因燃燒控制技術(如低氮燃燒器)而減少 30%-50%,同時避免了火炬燃燒產生的光污染和熱污染。部分發電機組配套的脫硫、脫硝裝置,可進一步凈化燃燒后的煙氣,使其排放濃度符合國家超低排放標準。這種以廢治廢的模式,幫助冶金企業完成減排指標,在環保政策日益嚴格的背景下,成為企業可持續發展的重要支撐。

Reducing pollutant emissions and promoting green production are its outstanding role in environmental protection, which meets the emission reduction requirements of the metallurgical industry. Traditionally, metallurgical enterprises often use torch combustion to discharge excess combustible gases, which not only wastes energy but also generates pollutants such as carbon dioxide and nitrogen oxides. Gas generator sets convert carbon monoxide into carbon dioxide by fully burning these gases (significantly reducing toxicity), and nitrogen oxide emissions are reduced by 30% -50% due to combustion control technologies such as low nitrogen burners, while avoiding light and heat pollution caused by torch combustion. The desulfurization and denitrification devices equipped with some generator sets can further purify the flue gas after combustion, making its emission concentration meet the national ultra-low emission standards. This waste to waste model helps metallurgical enterprises achieve emission reduction targets and becomes an important support for sustainable development in the context of increasingly strict environmental policies.

本文由燃氣發電機組友情奉獻.更多有關的知識請點擊:http://www.peldhb.com我們將會對您提出的疑問進行詳細的解答,歡迎您登錄網站留言.

This article is a friendly contribution from the analysis of gas generator sets For more information, please click: http://www.peldhb.com We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

業務分類

Business classification產品推薦

product recommendation聯系方式

Contact Information

截屏,微信識別二維碼