聯系 - 熱線

聯系 - 熱線

0531-69953988

聯系 - 熱線

聯系 - 熱線

焦爐煤氣發電機組發電的三種方式

一、目前國內焦爐煤氣綜合利用主要途徑有:

1、 At present, the main ways for comprehensive utilization of coke oven gas in China are:

(1)焦爐煤氣用作氣體燃料;

(1) Coke oven gas is used as a gas fuel;

(2)焦爐煤氣發電;

(2) Coke oven gas power generation;

(3)焦爐煤氣作為化工產品合成氣,主要有以下幾種工藝路線:

(3) As a synthetic gas for chemical products, coke oven gas mainly has the following process routes:

a:焦爐煤氣提氫聯產合成氨;

a: Coke oven gas hydrogen extraction combined with ammonia synthesis;

b:焦爐煤氣制甲醇,甲醇馳放氣提氫聯產合成氨;

b: Coke oven gas to produce methanol, methanol release gas to extract hydrogen and co produce synthetic ammonia;

c:焦爐煤氣甲烷化制LNG,副產少量氫氣;

c: Methanation of coke oven gas to produce LNG, producing a small amount of hydrogen gas as a byproduct;

d:焦爐煤氣液化(無甲烷化)制LNG,副產大量氫氣;

d: The liquefaction of coke oven gas (without methane) to produce LNG produces a large amount of hydrogen gas as a byproduct;

e:焦爐煤氣直接提取氫氣,剩余解析氣回焦爐,置換焦爐煤氣;

e: Directly extracting hydrogen from coke oven gas, and returning the remaining decomposed gas to the coke oven to replace coke oven gas;

二、焦爐煤氣綜合利用主要工藝及效益成本分析

2、 Main processes and cost-benefit analysis of comprehensive utilization of coke oven gas

2.1焦爐煤氣用作氣體燃料

2.1 Coke oven gas used as gas fuel

焦爐煤氣是優質的中熱值氣體燃料,其熱值為17兆焦~20兆焦/標準立方米,煤氣的主要成分(體積百分比)為氫55%~60%、甲烷19%~24%、一氧化碳5%~9%,另外含兩個以上的碳原子的不飽和烴2%~4%,目前,由于燃煤大部分地區受到環保限制,天然氣雖然熱值較焦爐煤氣高(約2倍),但天然氣使用成本較高,所以焦爐煤氣仍是工業生產的主要氣體燃料。如將焦爐煤氣用作陶瓷廠窯爐的加熱燃料,以及用作水泥和玻璃等工業生產的燃料。這種模式適合于焦化企業周邊有陶瓷、水泥、玻璃加工企業,通過脫硫、脫萘后加壓送往用熱單位,通過管道輸送維護費用較低,按銷售價0.6元/方計算,130萬噸焦炭副產外供焦爐煤氣40000方/小時,銷售額約2.4萬元/小時,年銷售收入2.1億元。經初步核算,焦爐煤氣通過脫硫、脫萘、加壓等綜合成本為約0.38元/方,扣除成本后,年產生的經濟效益約為7040萬元。

Coke oven gas is a high-quality medium calorific value gas fuel, with a calorific value of 17 megajoules to 20 megajoules per standard cubic meter. The main components (volume percentages) of the gas are hydrogen 55% to 60%, methane 19% to 24%, carbon monoxide 5% to 9%, and unsaturated hydrocarbons containing two or more carbon atoms 2% to 4%. Currently, due to environmental restrictions in most areas where coal is burned, although natural gas has a higher calorific value (about twice that of coke oven gas), its usage cost is higher. Therefore, coke oven gas is still the main gas fuel for industrial production. If coke oven gas is used as heating fuel for ceramic factory kilns, as well as fuel for industrial production such as cement and glass. This model is suitable for ceramic, cement, and glass processing enterprises in the vicinity of coking enterprises. After desulfurization and naphthalene removal, it is pressurized and sent to heat consuming units. The maintenance cost is relatively low through pipeline transportation. Calculated at a sales price of 0.6 yuan/cubic meter, 1.3 million tons of coke by-products are supplied to 40000 cubic meters/hour of coke oven gas, with a sales revenue of about 24000 yuan/hour and an annual sales revenue of 210 million yuan. According to preliminary calculations, the comprehensive cost of desulfurization, naphthalene removal, and pressurization of coke oven gas is about 0.38 yuan/cubic meter. After deducting the cost, the annual economic benefits generated are about 70.4 million yuan.

2.2利用焦爐煤氣發電

2.2 Utilizing coke oven gas for power generation

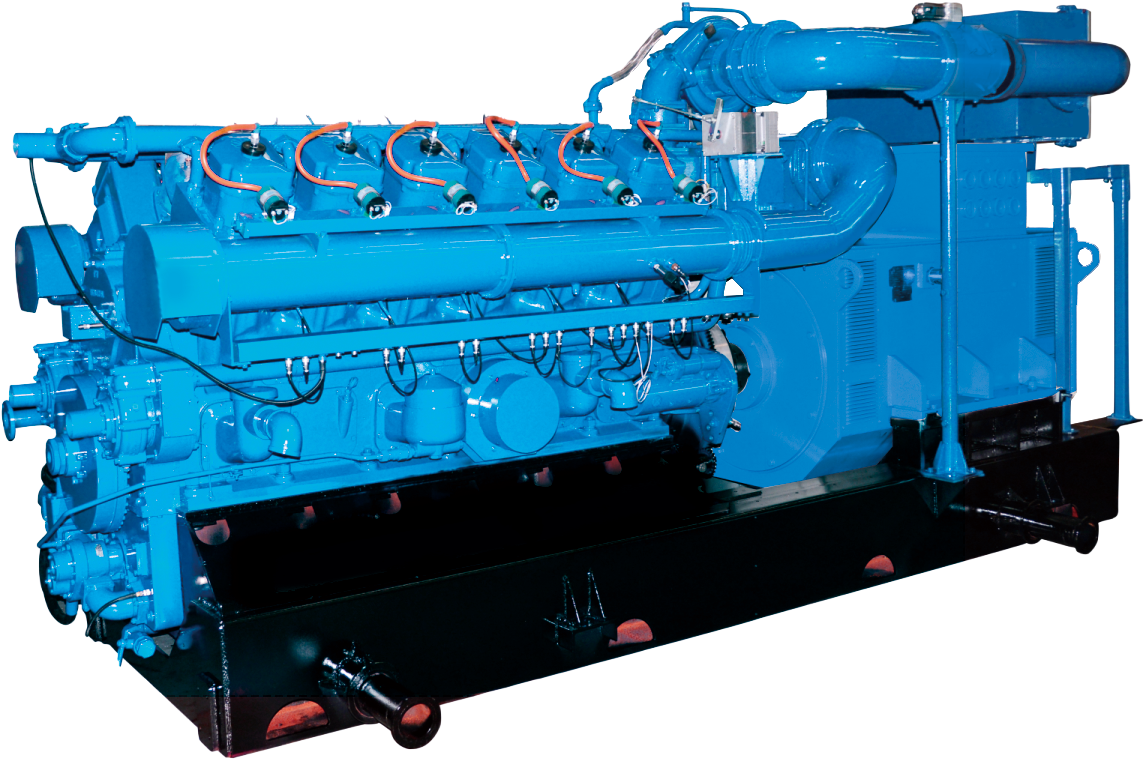

我國許多焦化企業將剩余的焦爐煤氣用于發電。焦爐煤氣發電有三種方式,分別為蒸汽發電(熱電聯產)、燃氣輪機發電和內燃機發電,目前這幾種發電方式在國內均有應用,技術成熟。如果焦化企業與高電耗生產匹配或與發供電企業聯營,且上網電價合適,焦爐煤氣用于發電可作為優先選擇的技術路之一。其運行與管理簡便,生產作業間長,可采取多種方式,企業收益穩定。

Many coking enterprises in our country use the remaining coke oven gas for power generation. There are three ways to generate electricity from coke oven gas, namely steam power generation (cogeneration), gas turbine power generation, and internal combustion engine power generation. Currently, these power generation methods are widely used in China and have mature technologies. If coking enterprises are matched with high electricity consumption production or jointly operated with power generation and supply enterprises, and the on grid electricity price is appropriate, using coke oven gas for power generation can be one of the preferred technological paths. Its operation and management are simple, the production operation is long, multiple methods can be adopted, and the enterprise's income is stable.

(1)蒸汽發電,熱電聯產供熱與發電兼用

(1) Steam power generation, combined heat and power generation for both heating and power generation

蒸汽發電由鍋爐-凝氣式氣輪機-發電機組成。該工藝以焦爐煤氣作為熱源燃燒鍋爐,生成高壓蒸汽,用以帶動汽輪機、發電機而發電。蒸汽發電技術過關、成熟可靠。在我國焦化行業應用較廣泛,但其系統復雜、占地面積大、啟動時間長。

Steam power generation consists of a boiler condensing gas turbine generator. This process uses coke oven gas as a heat source to burn boilers and generate high-pressure steam, which is used to drive steam turbines and generators to generate electricity. Steam power generation technology is mature and reliable. It is widely used in China's coking industry, but its system is complex, occupies a large area, and has a long start-up time.

(2)焦爐煤氣用于燃氣輪機發電

(2) Coke oven gas used for gas turbine power generation

燃氣輪機發電是用焦爐煤氣直接燃燒,驅動燃氣輪機以帶動發電機發電。燃氣輪機發電機組設備緊湊、占地少、效率高、效益好、啟動速度快。不過,燃氣輪機運行一段時間后必須遠距離運回制造廠檢修,因此需要較多的備品,要求工人有較高的技術素質。

Gas turbine power generation is achieved by directly burning coke oven gas to drive the gas turbine, which in turn drives the generator to generate electricity. The gas turbine generator set is compact, occupies less land, has high efficiency, good benefits, and fast starting speed. However, after running for a period of time, gas turbines must be transported back to the manufacturing plant for maintenance at a long distance, requiring a large number of spare parts and requiring workers to have high technical skills.

(3)燃氣——蒸汽聯合循環發電技術(CCPP)

(3) Gas Steam Combined Cycle Power Generation Technology (CCPP)

該技術的基本原理是將剩余的焦爐煤氣和回收的高爐煤氣經凈化、混合、加壓后送往燃氣輪機燃燒、膨脹做功,帶動燃氣輪發電機組發電。同時燃氣輪機排放的高溫煙氣加熱余熱鍋爐,產生蒸汽,帶動蒸汽輪發電機組,形成聯合循環發電。燃氣——蒸汽聯合發電是熱能資源的高效梯級綜合利用,其發電效率高達45%以上,實現了鋼電聯產,目前我國的濟鋼、寶鋼、太鋼、沙鋼、通鋼、鞍鋼、馬鋼、邯鋼安鋼、漣鋼等多家鋼廠都在使用該技術。

The basic principle of this technology is to purify, mix, and pressurize the remaining coke oven gas and recovered blast furnace gas before sending them to a gas turbine for combustion, expansion, and power generation, driving the gas turbine generator set to generate electricity. At the same time, the high-temperature flue gas emitted by the gas turbine heats the waste heat boiler, generates steam, and drives the steam turbine generator unit to form a combined cycle power generation. Gas steam combined power generation is an efficient cascade comprehensive utilization of thermal energy resources, with a power generation efficiency of over 45%, realizing the co production of steel and electricity. Currently, many steel mills in China, such as Jigang, Baosteel, Taiyuan Iron and Steel, Shagang, Tonggang, Ansteel, Magang, Handan Iron and Steel, and Lianyungang, are using this technology.

(4)用煤氣內燃機帶動發電機發電

(4) Using a gas internal combustion engine to drive a generator to generate electricity

我國一些焦化廠也有采用煤氣內燃機發電。可供選擇的焦爐煤氣內燃機發電機組有400千瓦、500千瓦、1200千瓦和2000年瓦。目前焦化行業大多采用的是500千瓦焦爐煤氣內燃機發電機組。按焦爐煤氣熱值(低熱值)16720千焦/立方米計算,1立方米焦爐煤氣可發電1.1千瓦時。

Some coking plants in our country also use gas internal combustion engines for power generation. The available options for coke oven gas internal combustion engine generator sets are 400 kW, 500 kW, 1200 kW, and 2000 kW. At present, the coking industry mostly uses 500 kW coke oven gas internal combustion engine generator sets. According to the calorific value (low calorific value) of 16720 kilojoules per cubic meter of coke oven gas, 1 cubic meter of coke oven gas can generate 1.1 kilowatt hours of electricity.

結論:焦爐煤氣熱值:4128Kcal/m3,即17255kJ/m3,鍋爐效率:80%,過熱蒸汽參數:溫度540℃;壓力9.8MPa;3475.4kJ/kg,即每萬方焦爐煤氣可產高壓蒸汽40t,每萬方焦爐煤氣可發電11000KWh,燃氣輪機發電效率高,發電成本低,但是前期投資大;余熱鍋爐發電前期投資小,但是發電效率較低,發電成本高。建議采取燃氣輪機發電的方式,減少煤氣放空、降低經濟損失。另外采取燃氣輪機和余熱鍋爐聯合發電的形式,該方案前期投資太大且經濟性不好。

Conclusion: The calorific value of coke oven gas is 4128Kcal/m3, which is 17255kJ/m3. The boiler efficiency is 80%, and the superheated steam parameters are at a temperature of 540 ℃; Pressure 9.8MPa; 3475.4kJ/kg, Each 10000 cubic meters of coke oven gas can produce 40 tons of high-pressure steam, and each 10000 cubic meters of coke oven gas can generate 11000 kWh of electricity. Gas turbines have high power generation efficiency and low power generation costs, but require large initial investment; The initial investment for waste heat boiler power generation is small, but the power generation efficiency is low and the power generation cost is high. Suggest adopting gas turbine power generation to reduce gas venting and minimize economic losses. Additionally, adopting a combination of gas turbines and waste heat boilers for power generation would result in excessive initial investment and poor economic viability.

本文由 焦爐煤氣發電機組 友情奉獻.更多有關的知識請點擊 http://www.peldhb.com/ 真誠的態度.為您提供為全面的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is a friendly contribution from a coke oven gas generator set For more related knowledge, please click http://www.peldhb.com/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

業務分類

Business classification產品推薦

product recommendation聯系方式

Contact Information

截屏,微信識別二維碼