聯系 - 熱線

聯系 - 熱線

0531-69953988

聯系 - 熱線

聯系 - 熱線

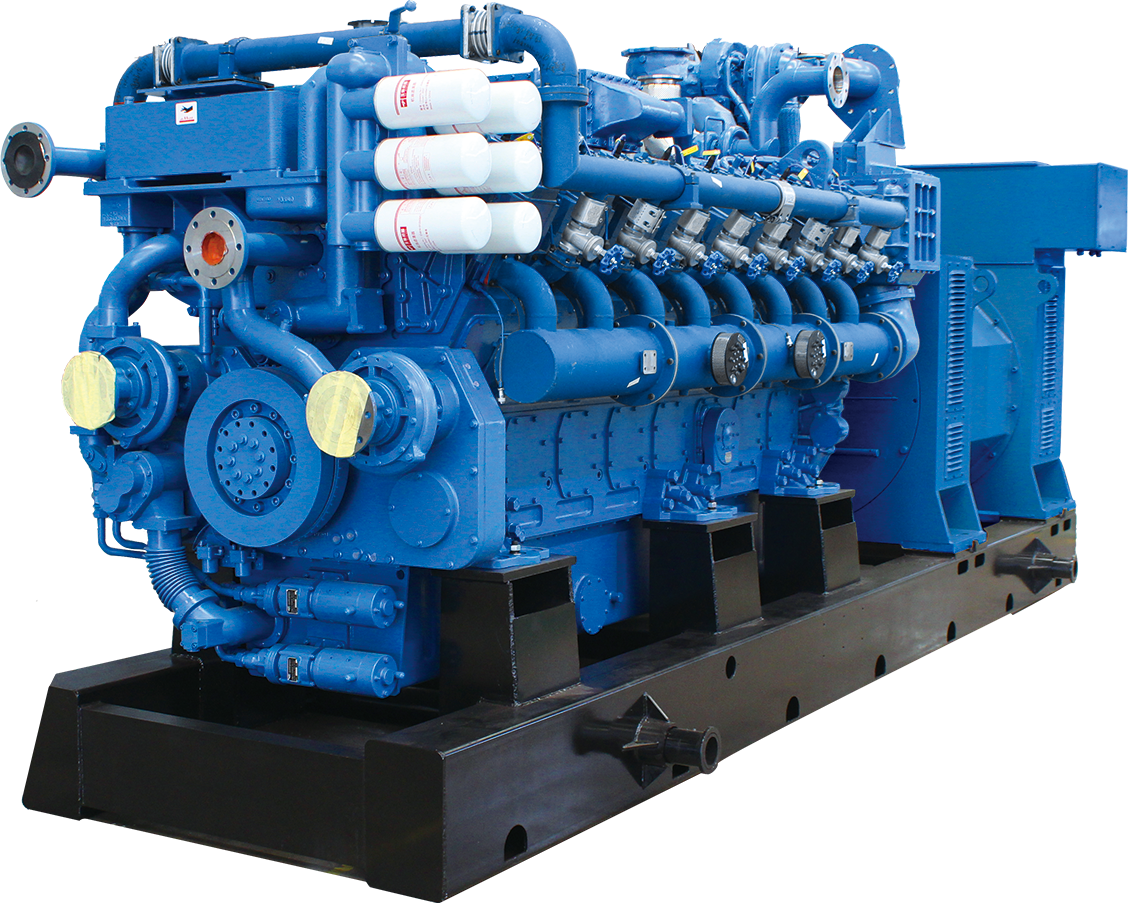

環能瓦斯發電機組的操作解析

環能瓦斯發電機組通過燃燒瓦斯(主要成分為甲烷)產生電能,兼具能源利用與環保價值,其操作需嚴格遵循流程規范,既保障運行安全,又提升發電效率。操作過程圍繞 “預處理 - 啟動 - 運行 - 停機” 四個核心階段展開,每個環節都需關注瓦斯濃度、壓力、溫度等關鍵參數,確保設備在穩定工況下運行。

The environmental energy gas generator unit generates electricity by burning gas (mainly composed of methane), which has both energy utilization and environmental value. Its operation must strictly follow the process specifications to ensure operational safety and improve power generation efficiency. The operation process revolves around four core stages: preprocessing, start-up, operation, and shutdown. Each stage requires attention to key parameters such as gas concentration, pressure, and temperature to ensure stable operation of the equipment.

操作前的準備工作是安全啟動的基礎,需從瓦斯預處理與設備檢查兩方面入手。瓦斯需經過過濾、脫水、穩壓處理:過濾器清除瓦斯中的粉塵、雜質,防止堵塞發動機噴嘴;脫水裝置分離瓦斯中的水分,避免液態水進入燃燒室影響燃燒效率;穩壓閥將瓦斯壓力控制在適宜范圍,過高易引發爆震,過低則燃燒不充分。設備檢查需覆蓋關鍵系統:潤滑系統需確認機油油位在標尺刻度范圍內,油質無乳化、雜質;冷卻系統檢查冷卻液液位與循環管路密封性,確保散熱功能正常;電氣系統測試啟動電機、蓄電池電壓及儀表顯示,保證信號傳輸準確。此外,需清理機組周圍雜物,保持通風良好,在操作區域配備滅火器材,設置 “嚴禁煙火” 警示標識。

The preparation work before operation is the foundation of safe start-up, which needs to start from two aspects: gas pretreatment and equipment inspection. Gas needs to be filtered, dehydrated, and stabilized: the filter removes dust and impurities from the gas to prevent clogging of the engine nozzle; The dehydration device separates the moisture in the gas to prevent liquid water from entering the combustion chamber and affecting combustion efficiency; The pressure regulator valve controls the gas pressure within an appropriate range. If it is too high, it can easily cause detonation, while if it is too low, it will result in incomplete combustion. Equipment inspection needs to cover key systems: the lubrication system needs to confirm that the oil level is within the scale range, and the oil quality is free of emulsification and impurities; Check the coolant level and the sealing of the circulation pipeline of the cooling system to ensure normal heat dissipation function; Test the starting motor, battery voltage, and instrument display of the electrical system to ensure accurate signal transmission. In addition, it is necessary to clean up the debris around the unit, maintain good ventilation, equip the operating area with fire extinguishing equipment, and set up a "no smoking" warning sign.

啟動過程需按步驟有序操作,避免因操作不當導致設備損傷。首先開啟瓦斯輸送閥門,通過流量計觀察瓦斯流量,緩慢調節閥門開度至規定值,同時監測瓦斯濃度。啟動前需進行預吹掃:開啟風機將機組內部殘留瓦斯排出,防止啟動時發生爆燃。隨后啟動發動機:按下啟動按鈕,觀察轉速表上升情況,若一次啟動失敗,需間隔 30 秒以上再嘗試,避免蓄電池過度放電。啟動成功后,怠速運行 2-3 分鐘,逐步提升轉速至額定值,期間密切關注機油壓力、水溫及瓦斯燃燒狀態。

The startup process should be operated in an orderly manner according to the steps to avoid equipment damage caused by improper operation. Firstly, open the gas delivery valve, observe the gas flow rate through the flowmeter, slowly adjust the valve opening to the specified value, and monitor the gas concentration at the same time. Pre blowing is required before starting: start the fan to discharge residual gas inside the unit to prevent explosion during startup. Then start the engine: Press the start button and observe the increase of the tachometer. If the start fails once, try again after an interval of more than 30 seconds to avoid excessive discharge of the battery. After successful startup, idle for 2-3 minutes, gradually increase the speed to the rated value, and closely monitor the oil pressure, water temperature, and gas combustion status during this period.

運行中的監控與調整直接影響發電效率與設備壽命。實時監測參數包括:瓦斯進氣壓力、進氣溫度、發動機缸體溫度、排氣溫度。發電系統需關注電壓、電流及頻率,確保輸出電力符合電網標準,當電網負荷變化時,通過調速器自動調整發動機轉速,維持頻率穩定。若出現瓦斯濃度驟降,機組應自動停機并發出報警,此時需檢查瓦斯源是否中斷或管路泄漏,排除故障后方可重新啟動。運行中需定期巡視,觀察管路連接處有無泄漏、機組振動是否異常,發現問題及時處理。

Monitoring and adjustment during operation directly affect power generation efficiency and equipment lifespan. Real time monitoring parameters include: gas intake pressure, intake temperature, engine cylinder temperature, and exhaust temperature. The power generation system needs to pay attention to voltage, current, and frequency to ensure that the output power meets the grid standards. When the grid load changes, the engine speed is automatically adjusted by the governor to maintain frequency stability. If there is a sudden drop in gas concentration, the unit should automatically shut down and issue an alarm. At this time, it is necessary to check whether the gas source is interrupted or if there is a pipeline leak. After troubleshooting, the unit can be restarted. Regular inspections should be carried out during operation to observe whether there are leaks at the pipeline connections and whether the unit vibration is abnormal. Any problems found should be dealt with in a timely manner.

停機操作需規范執行,避免對設備造成損傷。正常停機時,先逐步降低負荷,待機組運行平穩后,按下停機按鈕,同時關閉瓦斯進氣閥門,確保發動機停止后無瓦斯殘留。停機后需繼續運行冷卻系統 5-10 分鐘,待缸體溫度降至 60℃以下再關閉冷卻液循環,防止高溫部件驟冷變形。緊急停機適用于突發故障,立即按下緊急停機按鈕,切斷瓦斯供給與點火系統,同時記錄停機時間與故障現象,便于后續排查。

The shutdown operation should be carried out in a standardized manner to avoid damage to the equipment. When shutting down normally, gradually reduce the load first. After the standby group runs smoothly, press the stop button and close the gas intake valve to ensure that there is no gas residue after the engine stops. After shutdown, the cooling system needs to continue running for 5-10 minutes until the cylinder temperature drops below 60 ℃ before turning off the coolant circulation to prevent sudden cooling and deformation of high-temperature components. Emergency stop is suitable for sudden malfunctions. Press the emergency stop button immediately to cut off the gas supply and ignition system, while recording the downtime and fault symptoms for subsequent troubleshooting.

日常維護與操作規范相輔相成,需定期開展保養工作。每日檢查瓦斯過濾器壓差,超過規定值時更換濾芯;每周檢查火花塞積碳情況,清理或更換受損部件;每月檢測安全閥、壓力表等安全附件的靈敏性,確保符合安全標準。操作人員需經過專業培訓,熟悉機組結構與應急處理流程,嚴禁無證操作或擅自修改運行參數。

Daily maintenance and operational standards complement each other, and regular maintenance work needs to be carried out. Check the pressure difference of the gas filter daily, and replace the filter element when it exceeds the specified value; Check the carbon accumulation of spark plugs every week, clean or replace damaged parts; Monthly testing of the sensitivity of safety accessories such as safety valves and pressure gauges to ensure compliance with safety standards. Operators must undergo professional training, be familiar with the structure of the unit and emergency response procedures, and are strictly prohibited from operating without a license or modifying operating parameters without authorization.

本文由環能瓦斯發電機組友情奉獻.更多有關的知識請點擊:http://www.peldhb.com我們將會對您提出的疑問進行詳細的解答,歡迎您登錄網站留言.

This article is a friendly contribution from the analysis of gas generator sets For more information, please click: http://www.peldhb.com We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

業務分類

Business classification產品推薦

product recommendation聯系方式

Contact Information

截屏,微信識別二維碼