聯(lián)系 - 熱線

聯(lián)系 - 熱線

0531-69953988

聯(lián)系 - 熱線

聯(lián)系 - 熱線

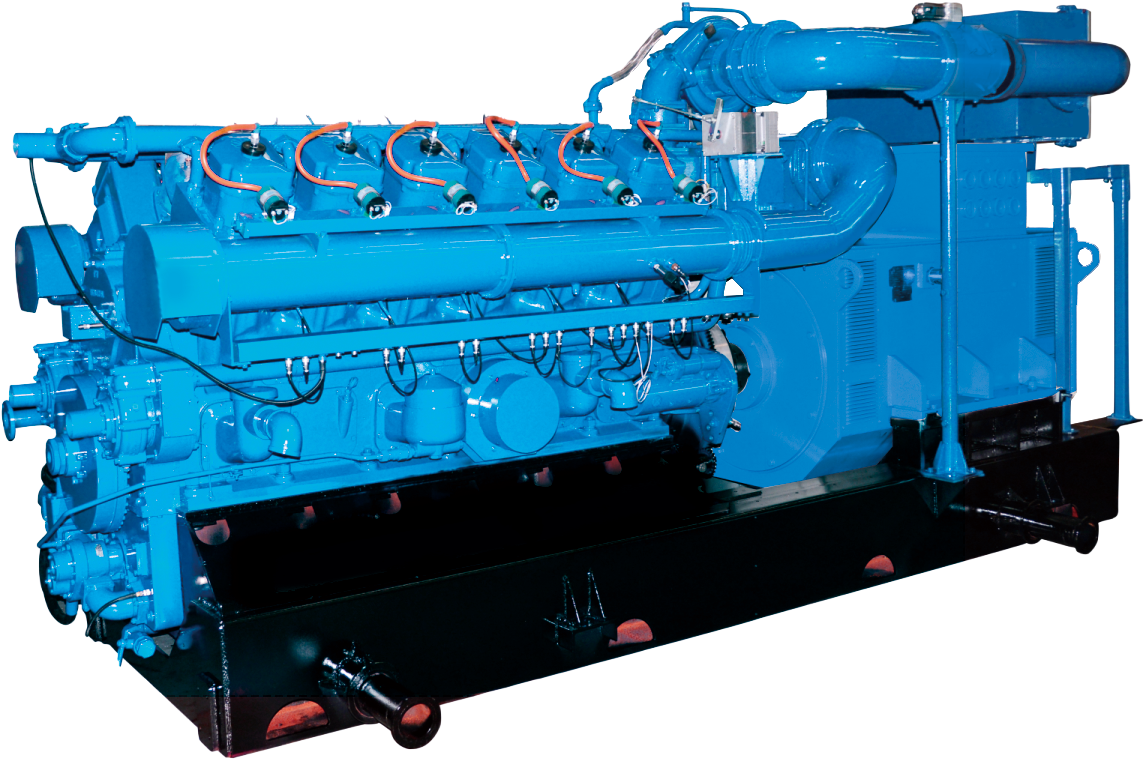

瓦斯發(fā)電機結構的相關解析

瓦斯發(fā)電機組是將瓦斯(如煤礦瓦斯、沼氣)的化學能轉化為電能的專用設備,其結構設計圍繞瓦斯的燃燒特性與能量轉化效率展開,由多個協(xié)同工作的系統(tǒng)組成,既需適應瓦斯?jié)舛炔▌拥奶攸c,又要保證運行安全與發(fā)電穩(wěn)定性,在能源回收與環(huán)保領域發(fā)揮著重要作用。

Gas generator set is a specialized equipment that converts the chemical energy of gas (such as coal mine gas and biogas) into electrical energy. Its structural design revolves around the combustion characteristics and energy conversion efficiency of gas, and is composed of multiple collaborative systems. It needs to adapt to the characteristics of gas concentration fluctuations, ensure operational safety and power generation stability, and play an important role in energy recovery and environmental protection.

進氣與預處理系統(tǒng)是瓦斯發(fā)電機組的 “氣源保障中樞”,負責將瓦斯安全導入并優(yōu)化燃燒條件。瓦斯通過管道輸送至機組,首先進入過濾裝置,濾網攔截氣體中的粉塵、水分及雜質(如煤顆粒、油霧),避免堵塞后續(xù)部件或影響燃燒效率,濾網需定期清理以保持透氣性。穩(wěn)壓裝置通過調節(jié)閥控制瓦斯流量,當氣源壓力波動時(如煤礦瓦斯抽采量不穩(wěn)定),自動調整閥門開度,將壓力穩(wěn)定在 0.1-0.3MPa,確保進入發(fā)動機的瓦斯量均勻。對于低濃度瓦斯(甲烷濃度 5%-30%),需配備摻混裝置,按比例混入空氣使甲烷濃度達到燃燒所需的 10%-15%,過高濃度易引發(fā)爆震,過低則無法穩(wěn)定燃燒,摻混后的氣體經混合器充分攪拌,形成均勻的可燃混合氣,為高效燃燒奠定基礎。

The intake and pre-treatment system is the "gas source guarantee center" of the gas generator set, responsible for safely introducing gas and optimizing combustion conditions. Gas is transported to the unit through pipelines and first enters the filtering device. The filter screen intercepts dust, moisture, and impurities (such as coal particles and oil mist) in the gas to avoid blocking subsequent components or affecting combustion efficiency. The filter screen needs to be cleaned regularly to maintain breathability. The stabilizing device controls the gas flow rate through regulating valves. When the gas source pressure fluctuates (such as unstable gas extraction in coal mines), the valve opening is automatically adjusted to stabilize the pressure at 0.1-0.3 MPa, ensuring uniform gas flow into the engine. For low concentration gas (methane concentration of 5% -30%), a blending device should be equipped to mix air in proportion to achieve the required methane concentration of 10% -15% for combustion. Excessive concentration can easily cause detonation, while insufficient concentration cannot stabilize combustion. The blended gas is thoroughly stirred by a mixer to form a uniform combustible mixture, laying the foundation for efficient combustion.

發(fā)動機本體是能量轉化的核心,通過內燃機原理將瓦斯燃燒的熱能轉化為機械能。氣缸與活塞構成燃燒空間,瓦斯混合氣進入氣缸后,被活塞壓縮至一定壓力(壓縮比通常為 8-10:1),壓縮終了時火花塞點火引燃混合氣,氣體急劇膨脹推動活塞做功,通過連桿帶動曲軸旋轉輸出機械能。針對瓦斯燃燒速度較慢的特點,發(fā)動機采用特殊的燃燒室設計 —— 半球形燃燒室增大火焰?zhèn)鞑ッ娣e,渦流進氣道使混合氣形成旋轉氣流,加快燃燒速度,減少未燃氣體排放。氣門機構由凸輪軸驅動,精確控制進排氣門的開啟與關閉時機,進氣門在活塞下行時打開吸入混合氣,排氣門在活塞上行時打開排出廢氣,氣門間隙需定期調整(通常 0.2-0.3mm),保證密封性能,避免漏氣導致功率下降。

The engine body is the core of energy conversion, which converts the thermal energy of gas combustion into mechanical energy through the principle of internal combustion engine. The cylinder and piston form a combustion space. After entering the cylinder, the gas mixture is compressed by the piston to a certain pressure (usually a compression ratio of 8-10:1). At the end of the compression, the spark plug ignites and ignites the mixture. The gas rapidly expands and pushes the piston to do work, which drives the crankshaft to rotate and output mechanical energy through the connecting rod. In response to the slow combustion speed of gas, the engine adopts a special combustion chamber design - a hemispherical combustion chamber to increase the flame propagation area, and a vortex inlet to form a rotating airflow of the mixture, accelerating the combustion speed and reducing unburned gas emissions. The valve mechanism is driven by the camshaft, which precisely controls the opening and closing timing of the intake and exhaust valves. The intake valve opens to suck in the mixture when the piston descends, and the exhaust valve opens to discharge the exhaust gas when the piston ascends. The valve clearance needs to be adjusted regularly (usually 0.2-0.3mm) to ensure sealing performance and avoid power reduction caused by air leakage.

排氣與凈化系統(tǒng)負責處理燃燒廢氣,減少環(huán)境污染并回收余熱。排氣管路采用耐高溫材料(如鑄鐵、不銹鋼),內壁光滑以減少排氣阻力,廢氣經排氣管進入催化轉化器,其中的貴金屬催化劑(如鉑、鈀)將有害氣體(一氧化碳、碳氫化合物)氧化為二氧化碳和水,凈化效率可達 90% 以上。對于大型機組,可配備余熱鍋爐,利用廢氣余熱加熱水產生蒸汽,用于供暖或驅動汽輪機二次發(fā)電,提高能源綜合利用率。排氣溫度監(jiān)測裝置實時監(jiān)控廢氣溫度,正常工況下溫度為 400-600℃,若溫度異常升高(如燃燒不良),系統(tǒng)會發(fā)出警報并調整燃燒參數(shù),防止部件過熱損壞。

The exhaust and purification system is responsible for treating combustion exhaust gases, reducing environmental pollution, and recovering waste heat. The exhaust pipe is made of high-temperature resistant materials (such as cast iron and stainless steel) with smooth inner walls to reduce exhaust resistance. The exhaust gas enters the catalytic converter through the exhaust pipe, where precious metal catalysts (such as platinum and palladium) oxidize harmful gases (carbon monoxide, hydrocarbons) into carbon dioxide and water, with a purification efficiency of over 90%. For large units, waste heat boilers can be equipped to use waste heat from exhaust gas to heat water and generate steam, which can be used for heating or driving steam turbines for secondary power generation, improving the comprehensive energy utilization efficiency. The exhaust temperature monitoring device monitors the exhaust gas temperature in real time. Under normal operating conditions, the temperature is between 400-600 ℃. If the temperature rises abnormally (such as poor combustion), the system will issue an alarm and adjust the combustion parameters to prevent component overheating and damage.

發(fā)電機與控制系統(tǒng)將機械能轉化為電能并實現(xiàn)自動化運行。發(fā)電機與發(fā)動機曲軸通過聯(lián)軸器連接,曲軸旋轉帶動發(fā)電機轉子轉動,切割磁感線產生交流電,經整流器轉換為直流電或通過逆變器輸出穩(wěn)定的 380V/220V 交流電,滿足不同用電需求。控制系統(tǒng)由傳感器、控制器和執(zhí)行器組成,實時監(jiān)測發(fā)動機轉速(通常 1500r/min)、水溫(80-90℃)、油壓等參數(shù),當出現(xiàn)超速、水溫過高或油壓過低時,立即發(fā)出警報并采取措施(如切斷瓦斯供應、停機),避免設備損壞。調速器根據(jù)負載變化調整發(fā)動機轉速,負載增加時加大瓦斯供應量并提高轉速,負載減少時則降低供應量,確保輸出電壓穩(wěn)定在 ±2% 范圍內,保證供電質量。

The generator and control system convert mechanical energy into electrical energy and achieve automated operation. The generator is connected to the engine crankshaft through a coupling, and the crankshaft rotates to drive the generator rotor to rotate, cutting magnetic induction lines to generate AC power. It is converted into DC power by a rectifier or output stable 380V/220V AC power through an inverter to meet different electricity needs. The control system consists of sensors, controllers, and actuators, which monitor engine speed (usually 1500r/min), water temperature (80-90 ℃), oil pressure, and other parameters in real time. When overspeed, high water temperature, or low oil pressure occurs, an alarm is immediately issued and measures are taken (such as cutting off gas supply, shutting down) to avoid equipment damage. The speed controller adjusts the engine speed according to changes in load. When the load increases, the gas supply is increased and the speed is increased. When the load decreases, the supply is reduced to ensure that the output voltage is stable within ± 2% and to guarantee the quality of power supply.

本文由瓦斯發(fā)電機組友情奉獻.更多有關的知識請點擊:http://www.peldhb.com我們將會對您提出的疑問進行詳細的解答,歡迎您登錄網站留言.

This article is a friendly contribution from the analysis of gas generator sets For more information, please click: http://www.peldhb.com We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

業(yè)務分類

Business classification產品推薦

product recommendation聯(lián)系方式

Contact Information

聯(lián)系我們

contact us

公司地址:山東省濟南市章丘區(qū)龍山街道潘王路24239號(龍山工業(yè)園八號路)

公司地址:山東省濟南市章丘區(qū)龍山街道潘王路24239號(龍山工業(yè)園八號路)

關注公眾號

企業(yè)二維碼

截屏,微信識別二維碼