聯(lián)系 - 熱線

聯(lián)系 - 熱線

0531-69953988

聯(lián)系 - 熱線

聯(lián)系 - 熱線

環(huán)能瓦斯發(fā)電機組的電量轉化:從可燃氣體到綠色電力的旅程

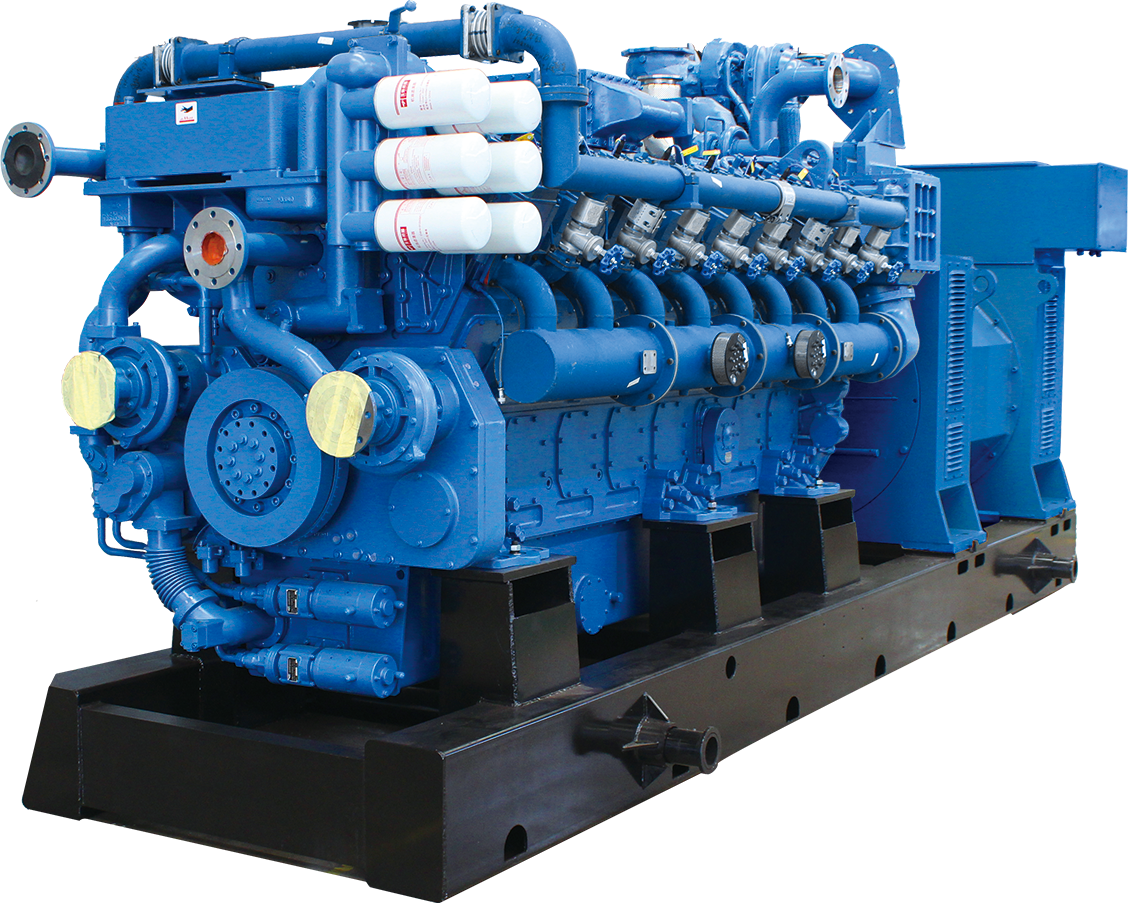

環(huán)能瓦斯發(fā)電機組作為處理可燃瓦斯氣體的能源裝備,通過精準的能量轉換過程,將瓦斯中的化學能逐步轉化為電能,同時實現(xiàn)氣體的安全利用(避免直接排放造成的安全隱患與溫室效應)。其核心原理是通過 “氣體凈化 - 燃燒做功 - 機電轉換” 的三級轉化,在確保瓦斯(主要成分為甲烷,濃度通常 30%-90%)安全處置的同時,實現(xiàn)能源的高效回收,單機發(fā)電量可達數(shù)百至數(shù)千千瓦,廣泛應用于工業(yè)尾氣與煤礦瓦斯的資源化利用場景。

As an energy equipment for processing combustible gas, the environmental energy gas generator unit gradually converts the chemical energy in gas into electrical energy through precise energy conversion process, while achieving safe utilization of gas (avoiding safety hazards and greenhouse effect caused by direct emissions). The core principle is to achieve efficient energy recovery through the three-stage conversion of "gas purification combustion work electromechanical conversion", while ensuring the safe disposal of gas (mainly composed of methane, with a concentration of usually 30% -90%). The single unit power generation can reach hundreds to thousands of kilowatts, which is widely used in the resource utilization scenarios of industrial exhaust gas and coal mine gas.

預處理系統(tǒng)為能量轉化提供合格 “燃料”,是穩(wěn)定發(fā)電的前提。瓦斯從收集管網(wǎng)輸送至機組后,首先進入過濾單元,通過多層濾網(wǎng)(精度 5-10μm)去除粉塵、水汽及液態(tài)雜質(zhì)(如煤焦油),防止發(fā)動機噴嘴堵塞(堵塞會導致燃燒不均勻,功率波動 ±5% 以上)。針對高硫瓦斯(硫化氫濃度>100ppm),需經(jīng)過脫硫裝置(如氧化鐵吸附或化學吸收法),將硫含量降至 50ppm 以下,避免腐蝕發(fā)動機缸體(未脫硫時缸體壽命縮短 30%-50%)。凈化后的瓦斯進入穩(wěn)壓罐(壓力維持在 5-20kPa,波動≤±1kPa),并與空氣按比例混合(空燃比 1:10-1:15,根據(jù)甲烷濃度動態(tài)調(diào)整),為燃燒系統(tǒng)提供穩(wěn)定的混合氣(熱值偏差≤5%)。

The preprocessing system provides qualified "fuel" for energy conversion, which is a prerequisite for stable power generation. After gas is transported from the collection pipeline network to the unit, it first enters the filtration unit and is filtered through multiple layers of screens (with an accuracy of 5-10 μ m) to remove dust, water vapor, and liquid impurities (such as coal tar), preventing engine nozzle blockage (blockage can cause uneven combustion and power fluctuations of ± 5% or more). For high sulfur gas (hydrogen sulfide concentration>100ppm), it needs to go through desulfurization equipment (such as iron oxide adsorption or chemical absorption method) to reduce the sulfur content to below 50ppm, avoiding corrosion of the engine cylinder block (the cylinder block life is shortened by 30% -50% without desulfurization). The purified gas enters the pressure stabilizing tank (maintained at 5-20kPa with fluctuations of ≤± 1kPa) and is mixed with air in proportion (air-fuel ratio 1:10-1:15, dynamically adjusted according to methane concentration) to provide a stable mixture for the combustion system (calorific value deviation ≤ 5%).

燃燒與動力輸出環(huán)節(jié)完成化學能到機械能的轉化,是能量轉換的核心。混合氣經(jīng)進氣閥進入發(fā)動機氣缸,在活塞壓縮至頂點時(壓縮比 10-12:1),被高壓電火花塞點燃(點火電壓 20-30kV),發(fā)生劇烈燃燒(火焰?zhèn)鞑ニ俣?30-50m/s),瞬間釋放熱能使缸內(nèi)溫度升至 1800-2200℃,壓力達 8-12MPa,推動活塞向下運動。通過曲柄連桿機構,活塞的往復運動轉化為曲軸的旋轉運動(轉速 1500-3000r/min),輸出機械扭矩。為適應瓦斯?jié)舛炔▌樱紵到y(tǒng)配備自適應調(diào)節(jié)功能:當甲烷濃度從 90% 降至 30% 時,自動增加進氣量(提升 200%)并延遲點火時刻(延后 5-10°CA),確保缸內(nèi)熱量輸入穩(wěn)定(波動≤±3%),維持輸出扭矩恒定。

The combustion and power output process completes the conversion of chemical energy to mechanical energy, which is the core of energy conversion. The mixture enters the engine cylinder through the intake valve, and when the piston is compressed to its peak (compression ratio 10-12:1), it is ignited by a high-voltage spark plug (ignition voltage 20-30kV), resulting in intense combustion (flame propagation speed 30-50m/s), instantly releasing heat energy to raise the cylinder temperature to 1800-2200 ℃ and pressure to 8-12 MPa, pushing the piston downward. Through the crank connecting rod mechanism, the reciprocating motion of the piston is converted into the rotational motion of the crankshaft (at a speed of 1500-3000r/min), outputting mechanical torque. To adapt to fluctuations in gas concentration, the combustion system is equipped with adaptive adjustment function: when the methane concentration drops from 90% to 30%, the intake air volume is automatically increased (increased by 200%) and the ignition timing is delayed (delayed by 5-10 ° CA), ensuring stable heat input in the cylinder (fluctuation ≤ ± 3%) and maintaining constant output torque.

發(fā)電系統(tǒng)將機械能轉化為電能,實現(xiàn)能源形式的最終轉換。發(fā)動機曲軸通過聯(lián)軸器驅(qū)動發(fā)電機轉子旋轉(同步轉速 1500r/min 對應 50Hz 交流電),轉子線圈在定子磁場中切割磁感線,產(chǎn)生三相交流電(電壓 400V,頻率 50Hz)。發(fā)出的電能先經(jīng)整流模塊轉換為直流電,再通過逆變器穩(wěn)壓調(diào)頻(精度 ±0.5%),確保輸出電能質(zhì)量符合標準(總諧波畸變率≤5%)。對需要并網(wǎng)的機組,還需配備同期裝置,使發(fā)電機輸出電壓、頻率與電網(wǎng)一致(相位差≤5°),實現(xiàn)平穩(wěn)并網(wǎng)(并網(wǎng)瞬間沖擊電流≤1.5 倍額定電流)。單機發(fā)電量根據(jù)機組功率而定,例如 1000kW 機組每小時可發(fā)電 1000 度,對應消耗瓦斯約 500-800 立方米(視甲烷濃度)。

The power generation system converts mechanical energy into electrical energy, achieving the ultimate conversion of energy forms. The engine crankshaft drives the generator rotor to rotate through a coupling (synchronous speed of 1500r/min corresponds to 50Hz AC power), and the rotor coil cuts magnetic induction lines in the stator magnetic field, generating three-phase AC power (voltage 400V, frequency 50Hz). The emitted electrical energy is first converted into direct current by a rectifier module, and then stabilized and frequency regulated by an inverter (with an accuracy of ± 0.5%) to ensure that the output electrical energy quality meets the standard (total harmonic distortion rate ≤ 5%). For units that need to be connected to the grid, synchronous devices should also be equipped to ensure that the output voltage and frequency of the generator are consistent with the grid (phase difference ≤ 5 °), achieving smooth grid connection (instantaneous surge current ≤ 1.5 times the rated current). The power generation of a single unit depends on the power of the unit. For example, a 1000kW unit can generate 1000 kWh of electricity per hour, corresponding to a gas consumption of about 500-800 cubic meters (depending on methane concentration).

余熱回收系統(tǒng)提升整體能源利用率,體現(xiàn) “環(huán)能” 特性。發(fā)動機運行中約 30%-40% 的能量以余熱形式存在:缸套冷卻水(溫度 80-90℃)和排氣(溫度 400-500℃)攜帶大量熱量,通過余熱鍋爐回收可產(chǎn)生 0.3-0.7MPa 的蒸汽(用于供暖或驅(qū)動輔助設備),使系統(tǒng)總能源利用率從單純發(fā)電的 30%-35% 提升至 60%-70%。部分機組還將余熱用于加熱瓦斯(從常溫升至 40-60℃),降低其相對濕度(從 90% 降至 60% 以下),避免管道內(nèi)結露堵塞,進一步優(yōu)化燃燒效率(提升 2%-3%)。

The waste heat recovery system improves the overall energy utilization efficiency and reflects the "environmental energy" characteristics. About 30% -40% of the energy generated during engine operation exists in the form of waste heat: the cylinder liner cooling water (temperature 80-90 ℃) and exhaust gas (temperature 400-500 ℃) carry a large amount of heat, which can be recovered by a waste heat boiler to produce steam of 0.3-0.7MPa (used for heating or driving auxiliary equipment), increasing the total energy utilization rate of the system from 30% -35% for pure power generation to 60% -70%. Some units also use waste heat to heat gas (from room temperature to 40-60 ℃), reduce its relative humidity (from 90% to below 60%), avoid condensation and blockage in pipelines, and further optimize combustion efficiency (increase by 2% -3%).

智能控制系統(tǒng)保障全程安全穩(wěn)定運行,是轉化過程的 “神經(jīng)中樞”。通過傳感器實時采集瓦斯?jié)舛龋z測間隔 1 秒,超標>1.5% 時停機)、缸體溫度(超過 90℃時啟動冷卻強化)、發(fā)電電壓與頻率等參數(shù),數(shù)據(jù)傳輸至中央控制器(響應時間<0.5 秒)。當檢測到瓦斯泄漏(濃度≥0.5%)或發(fā)動機故障(如超速、超壓),系統(tǒng)立即切斷進氣閥并啟動惰性氣體吹掃(如氮氣),同時觸發(fā)聲光報警,確保安全停機(停機時間<10 秒)。對多臺機組組成的電站,控制系統(tǒng)還能實現(xiàn)負荷分配(偏差≤2%),根據(jù)瓦斯產(chǎn)量自動調(diào)整運行臺數(shù),避免能源浪費。

The intelligent control system ensures safe and stable operation throughout the entire process, and is the "nerve center" of the transformation process. Real time collection of gas concentration (with a detection interval of 1 second, shutdown when exceeding the standard by more than 1.5%), cylinder temperature (starting cooling enhancement when exceeding 90 ℃), power generation voltage and frequency parameters through sensors, and data transmission to the central controller (response time<0.5 seconds). When gas leakage (concentration ≥ 0.5%) or engine failure (such as overspeed or overpressure) is detected, the system immediately cuts off the intake valve and starts inert gas purging (such as nitrogen), while triggering an audible and visual alarm to ensure safe shutdown (shutdown time<10 seconds). For power stations composed of multiple units, the control system can also achieve load distribution (deviation ≤ 2%), automatically adjust the number of operating units according to gas production, and avoid energy waste.

本文由環(huán)能瓦斯發(fā)電機組友情奉獻.更多有關的知識請點擊:http://www.peldhb.com我們將會對您提出的疑問進行詳細的解答,歡迎您登錄網(wǎng)站留言.

This article is a friendly contribution from the analysis of gas generator sets For more information, please click: http://www.peldhb.com We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

業(yè)務分類

Business classification產(chǎn)品推薦

product recommendation聯(lián)系方式

Contact Information

聯(lián)系我們

contact us

公司地址:山東省濟南市章丘區(qū)龍山街道潘王路24239號(龍山工業(yè)園八號路)

公司地址:山東省濟南市章丘區(qū)龍山街道潘王路24239號(龍山工業(yè)園八號路)

關注公眾號

企業(yè)二維碼

截屏,微信識別二維碼